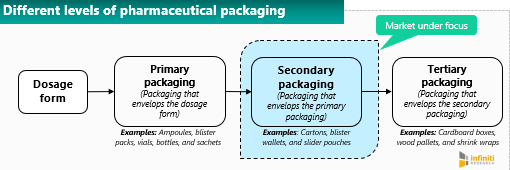

In pharmaceuticals, secondary packaging constitutes the packaging that does not come in direct contact with the dosage form. Pharma secondary packaging is becoming widely adopted and essential as they offer critical functionalities, such as, physical and barrier protection, secondary containment, adherence to regulations, and consumer safety. It also creates a buffer and protects primary packages from each other during transportation.

Challenges faced by the pharma secondary packaging company

A prominent pharmaceutical company headquartered in San Francisco, CA sought to explore the changing trends in the secondary pharma packaging market by focusing the research on major design/technology innovations and best practices adopted by leading players in the pharma secondary packaging market. Through the engagement, the client wanted to support their future packaging developments and track industry trends over time. By leveraging Infiniti’s competitive intelligence solution, the pharmaceutical company wanted to understand the competitor landscape in the US and European pharma secondary packaging market, new features of secondary packaging being incorporated by competitors, product portfolio descriptions, and competitor strategies to promote adherence.

Want comprehensive insights into the market drivers, challenges, key industry players, and more in the pharma secondary packaging market? Request a complimentary proposal.

Our Approach

Experts at Infiniti Research started by delving deeply into the pharma secondary packaging market transformation over the past decade in the US and Europe. This involved a well-balanced combination of primary and secondary research. Telephonic discussions were undertaken with over 45 respondents with expertise in the development, sales, marketing, and usage of products and services related to secondary packaging market such as pharmaceutical packaging specialists, packaging engineers, and packaging development experts. The secondary research undertaken by our analysts included comprehensive research materials from company websites, industry news CPA, HCPC, CHPA, packaging digest, and public database.

Through extensive competitive intelligence study and research methodologies, experts at Infiniti Research were able to identify the top packaging designs that are predominantly used. This includes medication adherence packaging, extended labels, and increasing use of sustainable materials in pharma secondary packaging. Furthermore, Infiniti’s competitor landscape assessment also identified some of the key competitors in the US and Europe, their respective packaging initiatives, and critical initiative undertaken to promote adherence.

With a focus to ensure product integrity, better manufacturing efficiency, and enhancing customer satisfaction, experts at Infiniti Research have identified that companies are developing innovative technologies such as thermochromic indicators and contemporary cartons designs. Furthermore, with Infiniti’s recommendation, the client adopted robotics and process automation that significantly improves production output, lowers operating costs, and enhances worker safety.

Business Impact

By leveraging Infiniti’s competitive intelligence solution, the client was able to successfully track their key market competitors and identify some of the most innovative and viable trends in the pharma secondary packaging market. Apart from this client was also able to:

- Increase investments by adopting technologies which result in faster turn-around time, fewer errors, and higher adaptability to incorporate and reproduce design changes

- Collaborate with the CPO to formulate innovative packaging designs which are senior-friendly, child- resistant, medication adherence promoting, and offers unique dispensing mechanisms

- Expedite early market entry for biologics and personalized medicine by identifying advancements such as 3D printing in pharmaceutical packaging

- Reduce operational cost by 30% within this first quarter by adopting RPA into packaging operations

- Focus on packaging designs that are cost-effective and have shorter production turnaround times

- Incorporate adherence features in the secondary packaging design to help practitioners promote the use of the drugs to the patients

- Build an effective planning and production process to minimize packaging errors and prevent product recalls, saving the company over $1.2 million within six months

For similar engagements for your business, get in touch with an industry expert