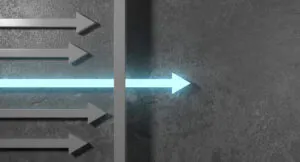

Liquid filters are devices or systems used to remove impurities, contaminants, or unwanted particles from liquids. They are essential for ensuring product quality, protecting equipment, and maintaining safety across industries like water treatment, pharmaceuticals, food processing, and manufacturing. Below are the main types of liquid filters:

Types of Liquid Filters

Mechanical Filters

- Use physical barriers (e.g., cloth, paper, porous membranes) to trap solid particles while allowing liquids to pass through.

- Examples include depth filters (capture particles throughout their thickness) and surface filters (trap particles on their surface).

Cartridge Filters

- Employ replaceable cartridges with specific micron ratings for fine particle removal.

- Made from materials like polypropylene (PP) or polyethersulfone (PES), these filters are widely used in industries requiring high-quality purification.

Membrane Filters

- Utilize thin, porous membranes with precise pore sizes for separating particles based on size and molecular weight.

- Effective for removing microorganisms, bacteria, and viruses, with applications in pharmaceuticals and water treatment.

Activated Carbon Filters

- Use activated carbon to adsorb organic compounds, chemicals, odors, and colorants from liquids.

- Commonly employed in water treatment to improve taste and remove chlorine.

Gravity Filters

Rely on gravity to separate impurities; examples include sand-bed filters used in municipal water treatment systems.

Pressure and Vacuum Filters

Operate under pressure or vacuum to enhance filtration efficiency, often used for industrial applications.

Liquid filters play a critical role in various processes by ensuring cleanliness, safety, and compliance with industry standards. Their selection depends on factors like the type of liquid being filtered, desired purity levels, and operational requirements.

Discover reliable filtration solutions to achieve cleaner and more efficient results for your needs in our latest whitepaper!